We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Our Supply Chain

In order to guarantee the best quality, FTC® monitors the extraction of the raw material by its own employees. The extraction takes place in Shaanxi province. Not only do the farming of Cashmere goats and the production of raw materials provide the economic basis for a large part of the population, but they also allow the inhabitants to continue living their centuries-old culture that is connected to nature. It is therefore only reasonable to process cashmere where this noble raw material originates. Our full supply chain is owned and managed by FTC®, which provides us with the opportunity to perfect every step to fit our standards; all in a fair, sustainable and responsible way.

OWN MANUFACTURE

- OUR POWER

CASHMERE AS A MATTER OF TRUST

Today, FTC® is not only a cashmere brand, but also a cultural project with sustainable structures from correct keeping of animals to the final end product. FTC® is therefore very proud of all those involved in this project and the respect they have for each other. From farmer to customer, FTC® lives fair trade. Long-standing business partnerships play an important role in ensuring the consistently high quality of the products, as does constant monitoring of the standards of the goods.

Climate-Neutral Products and Transparency

Everything starts in the heights of Shaanxi in China. The animals are fed on alfalfa and corn, which FTC® grows near the farm. With a specially developed set of animal farming rules, FTC® also takes responsibility for treating its animals well. To further ensure animal welfare, FTC® cooperates with national universities and has the health of the cashmere goats regularly checked by specialists.

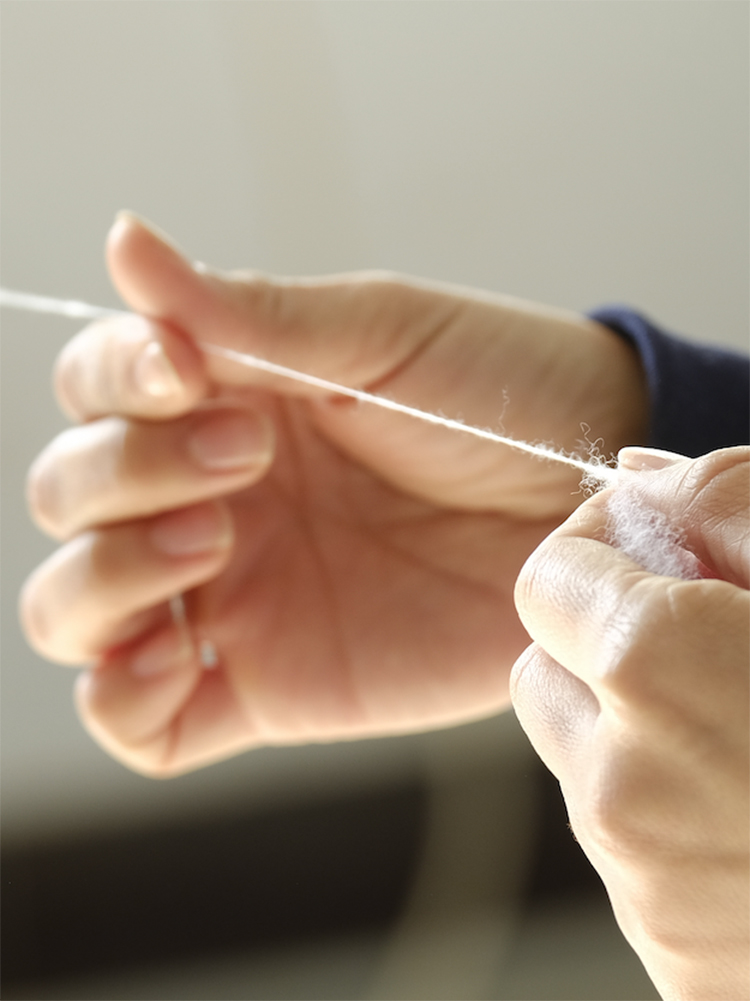

The fine underhairs of the cashmere goats are obtained annually at the change of season from winter to summer with a lot of patience and care. The knowledge about the cashmere goat is passed down through generations by our employees.

From carding and dyeing, to spinning and knitting - all process steps of the processing to the fashion piece take place in the own manufactory in the Chinese province of Hebei. The own manufactory enables transparency, control and overview for FTC®. Only very few middlemen, for product ingredients like buttons, are involved along the way.

THE FINISHED GARMENT

COMBING IN SPRING

Excellent cashmere quality starts with the choice of goat. That is why FTC® only uses raw materials from animals that come from its own goat breeding. The company's own cashmere goat farm in Shaanxi and the Farmer Protection Programme ensure the consistent top quality of the animals bred, as well as animal welfare. Furthermore, the farmers are offered an adequate, secure and long-term income opportunity. The animals get a medical checkup every two weeks to make sure they are well and healthy.

Cashmere harvesting takes place annually between April and June. The fine underhair of the goats is combed out and pre-sorted according to different quality categories. The combed-out undercoat forms the basis for the cashmere material. Approximately 300-400 grams of final raw material are obtained from one goat per year. The youngest goats give the particularly fine and exclusive baby cashmere.

WASHING, CARDING & SORTING

The raw material is transported to the FTC® manufactory in the nearby province of Hebei (CN), where the further process steps take place. After washing the first raw material and after carding (machine combing of the first raw material) 8 to 12 times, the final raw material is ready for further proceeding.

The fineness and the length of the hair determine the quality of cashmere. These steps happen in the company‘s facilities as well. The electricity used for this is partly generated by the solar panels on the plants‘ roof.

DYEING

The natural shades of cashmere wool are brown and white.The fibres can be dyed as raw material (flake dye), yarn (yarn dye) or as a finished product (piece dye). FTC® dyes the final raw material only as fluff in the flake dye process exclusively in the company‘s own dyeing plant. Although this process is more time-consuming, the colours are more brilliant and vibrant and the softness of the cashmere is better preserved. Ultimately, this is the best quality for dyeing. The water used is purified with a water treatment plant before being reintroduced into the groundwater. We are currently in a testing phase for natural colorants to test a broader color spectrum and variations.

In addition, FTC® offers some articles made of Natural Yarn. For these products, the cashmere raw material was neither dyed nor bleached, so that the natural original colour of the cashmere is completely preserved.

SPINNING

The final cashmere dyed material is spun in a complex spinning process, which takes also place in our plant in Hebei.

KNITTING & LINKING

FTC® styles are knitted fully-fashioned on the modern flat knitting machines. Particularly time-consuming is the manual work of the subsequent linking, with which the knitted pieces are joined together. By not cutting and sewing the garments, we already achieved minimum production waste.

Thanks to our UpKnit collection, we’ve reached a zero-waste production, where the yarn leftovers from the knitting process are upcycled into colorful and unique styles.

PACKAGING PRODUCTS

Commitment to sustainability has been an important issue for FTC® since the company was founded. In order to keep its ecological footprint a little smaller, FTC® switched its product packaging to recyclable paper bags. Bags made of strong, unbleached, FSC-certified kraft paper replace the polybags previously used with the aim of reducing plastic consumption, minimising waste and making the packaging more environmentally friendly. The packaging is used in different sizes to ensure that it fits the product as well as possible and thus also creates less waste.

WEAR & CARE

Finally, the last step is delivering our FTC® designs to a happy client. Buying your garments sustainability and longevity in mind is a great step towards a more mindful fashion consumption. Another important step is knit caretaking. Washing your knit-styles with appropriate detergents, in suitable washing bags and regularity pilling your knits all have a big impact on the state of your garment over time. Have a look at our Care Collection and care for what you love with the use of our Care Guide.